Supply chains face relentless pressure. Teams manage volatile lead times, strict compliance, and nonstop digital alerts. The result often includes stress, sleep disruption, and burnout. Leaders now see mental health as an operational risk. Clear sourcing strategies, verified partners, and transparent data reduce uncertainty. They also protect the people who run the system.

This guide highlights the top industrial growth sectors in 2026 and shows how to build resilient, carbon-conscious supply chains without overloading your team. Each section offers practical sourcing steps, factory verification tips, and concrete examples you can adapt in your business.

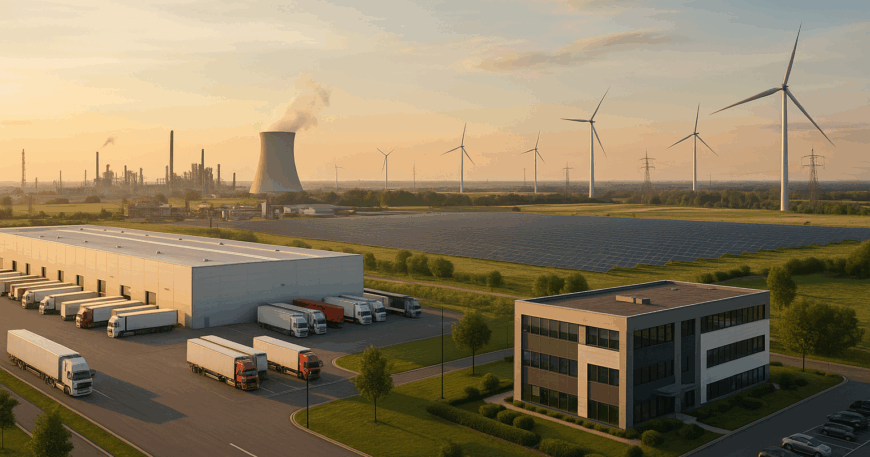

Renewable Energy and Storage in 2026

Why this sector leads growth

Governments and corporates will expand solar, wind, and battery projects through 2026. Grid operators need flexible storage. Utilities need faster interconnects. Industrial buyers need on-site power security. Component demand will surge across PV modules, inverters, power electronics, battery cells, enclosures, and balance-of-system hardware.

Sourcing playbook for renewables

- Source core components from dual regions to reduce policy and port risk.

- Qualify Tier 1 and Tier 2 suppliers for cells, packs, BMS, and power semiconductors.

- Specify traceable, low-carbon materials for frames, racks, and cabling.

- Use factory verification to validate cell chemistry provenance and test protocols.

- Align Incoterms with project cash flow and site commissioning windows.

Compliance and carbon strategy

- Map lifecycle CO2e for panels, inverters, and batteries to meet tenders with carbon thresholds.

- Request EPDs, RoHS, REACH, and country-of-origin documentation at the RFQ stage.

- Audit recycling partners for modules and packs to meet extended producer responsibility rules.

Example: resilient battery storage sourcing

A European EPC needed energy storage containers for a 50 MW project. We built a dual-supplier model for enclosures in Türkiye and Vietnam and qualified a BMS partner in Taiwan. Our team verified UN 38.3 and IEC 62619 test records and witnessed thermal runaway tests. We designed a staggered shipment plan around port congestion and secured alternative ports. The project cut delivery risk and met a tight commissioning date. The EPC also reduced embodied carbon by switching to recycled aluminum rails.

Semiconductors, Power Electronics, and AI Hardware

Market drivers in 2026

AI infrastructure, EV platforms, and industrial automation will lift demand for chips and power electronics. Growth centers include advanced packaging, silicon carbide devices, servers, edge compute, and high-efficiency power supplies. Capacity will expand across the US, EU, Japan, South Korea, and Southeast Asia, while back-end assembly and test remain geographically diverse.

How to secure supply and control risk

- Build a bill of materials map that tags each part with fab location, packaging site, and alternates.

- Pre-qualify Form-Fit-Function replacements for critical ICs and MOSFETs to avoid redesign delays.

- Use die banks and vendor-managed inventory for long lead items during ramp phases.

- Add contract manufacturers in Mexico or Eastern Europe for regionalization and tariff agility.

- Verify traceability to fight counterfeits through serialization and direct-from-OEM channels.

Compliance checkpoints

- Screen parts and suppliers against export control lists, de minimis thresholds, and end-use rules.

- Secure certificates for safety, EMC, and energy efficiency for server and power systems.

- Document conflict minerals, REACH SVHC, and PFAS status at sourcing, not post-award.

Example: AI server build of materials stabilization

A cloud provider faced six-month delays on power modules and retimers. We introduced dual-source options, locked a wafer start program with the OEM, and moved subassembly to a nearshore EMS. Our team verified ESD control and humidity bake protocols on site. Lead time dropped by 38 percent, and the client avoided paying spot market premiums for critical ICs.

Green Construction Materials and Building Systems

Why construction materials will surge

Infrastructure upgrades and real estate retrofits will gain speed. Developers seek lower embodied carbon and faster installation. Demand rises for low-carbon cement, recycled steel, mass timber, high-performance insulation, heat pumps, and smart building controls. Public projects include carbon criteria, which reshape sourcing decisions.

Sourcing approach for low-carbon materials

- Benchmark EPDs across regions and negotiate verified CO2e per ton for steel and cement.

- Source mass timber with chain-of-custody certification and verify kiln schedules for stability.

- Use modular MEP skids and pre-insulated piping to shorten site work and reduce labor risk.

- Qualify heat pump suppliers on seasonal efficiency, refrigerant type, and service networks.

- Set packaging specs for safe, compact shipments to lower breakage and freight emissions.

Factory verification essentials

- Audit mill test certificates and sampling procedures for structural steel and rebar.

- Witness cement blending ratios and curing controls for alternative binders.

- Run dimensional checks and glue-line testing on CLT and GLT panels.

- Verify ERP traceability from raw material to finished lot to support site inspections.

Example: public tender with carbon criteria

A contractor bidding a transport hub needed concrete with strict embodied carbon limits. We sourced cement substitutes and negotiated slag availability. Our team validated plant dosing systems and set a pre-shipment sampling plan. The contractor won the tender with a compliant mix and fixed delivery windows, which reduced crew idle time and team stress.

Healthcare, MedTech, and Biopharma Equipment

Growth outlook for 2026

Diagnostics, single-use bioprocessing, wearables, home care devices, and cold chain equipment will expand. Hospitals and labs prefer suppliers with strong quality systems and reliable aftersales support. Regulators raise expectations for documentation and traceability.

Quality and compliance you need on day one

- Source from ISO 13485 and GMP certified plants and confirm management review cadence.

- Validate sterilization providers and maintain dose audits and biological indicators.

- Set UDI and serialization early to align with market registrations.

- Implement cleanroom controls and particle monitoring with electronic batch records.

- Design packaging for ISTA standards to protect sensitive devices in cold chain transit.

Import and export control steps

- Confirm ECCN and HS codes, licensing needs, and controlled pathogen handling rules.

- Define Incoterms that fit validation schedules, especially when you need site acceptance tests.

- Set a deviation management process so quality teams react fast without burnout.

Example: single-use system scale-up

A bioprocessing firm scaled filters and bags for a new line. We qualified two sterile converters and a resin supplier with change control agreements. Our team verified cleanroom behavior, lot traceability, and gamma sterilization partners. On-time delivery reached 98 percent while audit findings dropped. The client avoided emergency weekend work and improved team well-being.

Circular Economy, Recycling, and Industrial Reuse

Why circular flows will grow in 2026

Policies and investors now reward recycled content, repair, and take-back programs. Battery recycling scales with EV adoption. E-waste rules expand producer responsibility. Industrial buyers seek closed-loop alloys, plastics, and solvents to cut costs and emissions.

Building circular supply chains

- Map feedstock availability and purity levels by region for metals, polymers, and electrolytes.

- Qualify recyclers on safety, material balance, and downstream offtake agreements.

- Design products for disassembly and standardize fasteners to speed recovery.

- Use digital passports for materials to prove recycled content and track CO2e.

- Contract reverse logistics with KPIs on collection rate, sort accuracy, and time to reuse.

Compliance and documentation

- Check Basel Convention requirements for transboundary waste shipments.

- Secure permits for hazardous fractions and confirm treatment chain custody.

- Include post-consumer recycled content claims in supplier contracts with audit rights.

Example: closed-loop metals for power enclosures

An industrial OEM wanted recycled aluminum and steel for outdoor enclosures. We partnered with a regional recycler and a certified mill. Our team set melt schedules and alloy controls, then verified EPDs. The OEM achieved 60 percent recycled content, cut CO2e per unit, and locked pricing against virgin metal swings. Teams spent less time fire-fighting cost spikes.

Actionable steps you can deploy this quarter

- Create a critical parts register with dual sourcing targets and approval dates.

- Launch factory verification for top suppliers and tie findings to clear corrective actions.

- Set a carbon bill of materials for one product line and track CO2e per part.

- Pilot a nearshore or dual-region assembly for a high-margin SKU.

- Train teams on Incoterms, export controls, and documentation to prevent delays.

How this approach supports team mental health

Clarity reduces stress. When you define alternates, documentation, and audit schedules, your team avoids weekend crises. You improve response time and morale. You keep talent and build a learning culture.

How The Prime Sourcing helps

- International sourcing across Asia, Europe, and the Americas with verified suppliers.

- Carbon-neutral supply chain design with lifecycle CO2e tracking and EPD support.

- Factory verification and product inspection with digital reports and corrective action plans.

- Import and export compliance, including HS classification, ECCN, and license management.

- Production optimization, line balancing, and supplier development for stable output.

- Construction material sourcing with low-carbon options and transparent documentation.

- Industry insights tailored to your sector and growth targets for 2026.

You can move fast and keep control. You can meet carbon targets and cut risk. You can support your team and still hit growth numbers. If you want a focused plan for any of the sectors above, our team can help you design and execute it.

FAQ for 2026 industrial sourcing

Which sectors will scale the fastest in 2026

Renewable energy and storage, semiconductors and power electronics, green construction materials, healthcare and medtech, and circular economy solutions will lead growth.

How do I combine carbon targets with cost control

Compare EPDs, negotiate verified CO2e, and secure recycled content where performance allows. Use logistics modes with lower emissions and optimize packaging to reduce waste and freight cost.

What reduces supply risk the most

Dual sourcing, supplier development, factory verification, and clear alternates for critical parts. Add nearshore options for resilience and faster response.

How do I protect my team from burnout

Standardize SOPs, automate documentation checks, set realistic buffers, and align stakeholders on change control. Clear processes cut late requests and crisis work.

If you want sector-specific supplier shortlists, audit programs, or a carbon bill of materials, reach out. We will respond with a simple plan, timelines, and measurable outcomes.

Ready to start today

Contact The Prime Sourcing

for a quick, focused consultation.